Custom packaging is the silent ambassador of your brand—transforming containment into crave-worthy experiences. In an age where 78% of consumers judge product quality by packaging (IPSOS, 2024), bespoke designs act as visual magnets that capture attention in 0.67 seconds (Sensory Logic) and elevate perceived value by up to 89%. Luxury leaders like Tiffany leverage signature robin-blue boxes to command 30% price premiums, while Dior’s textured perfume packs boost Gen Z retention by 41%. Beyond aesthetics, it forges memory imprints: tactile finishes activate the brain’s recall centers 3.2x stronger than visuals alone (Journal of Consumer Psychology). When 68% of customers develop emotional bonds through unboxing rituals (Forrester), custom packaging becomes the ultimate brand amplifier—converting shipments into shareable moments that cement loyalty and accelerate social discovery.

Custom packaging is the silent ambassador of your brand.

Precision cutting raw paperboard to press-readywidths (士0.5mm tolerance)

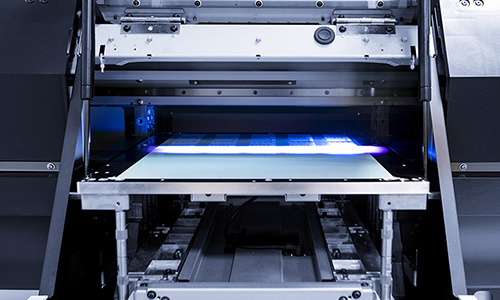

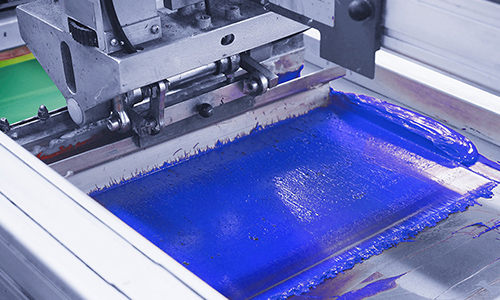

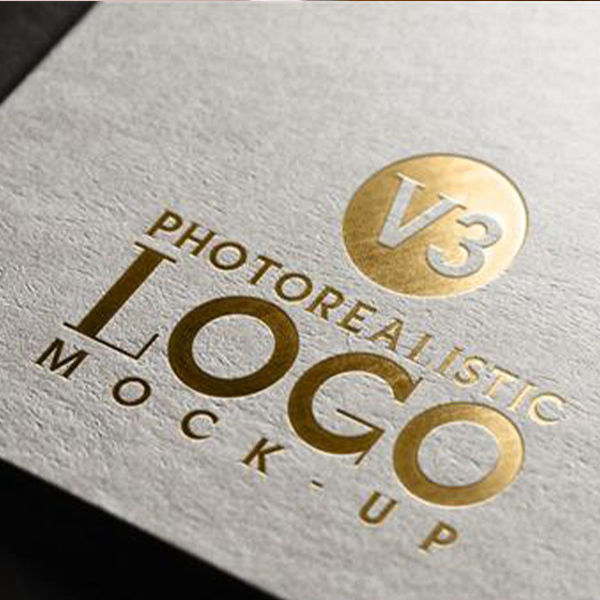

CMYK / Pantone offset printing with color accuracy

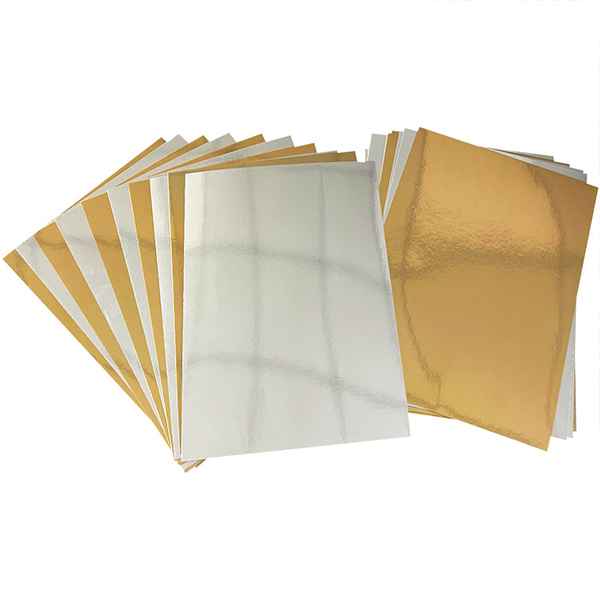

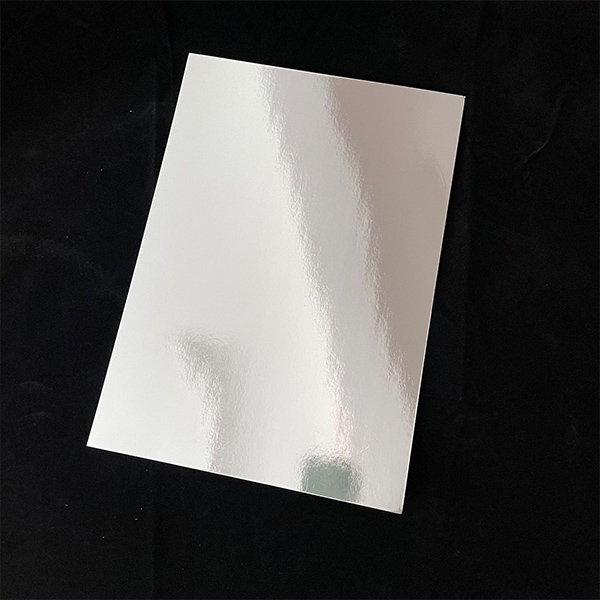

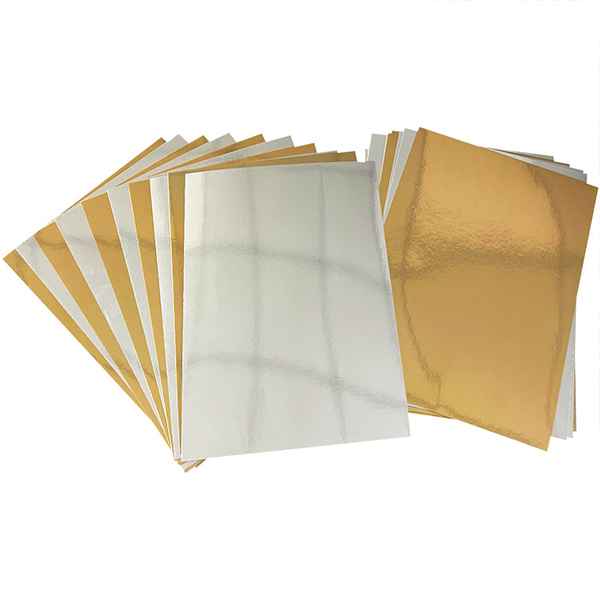

Bonding BOPP/PE films for scratch resistance (gloss/matte options)

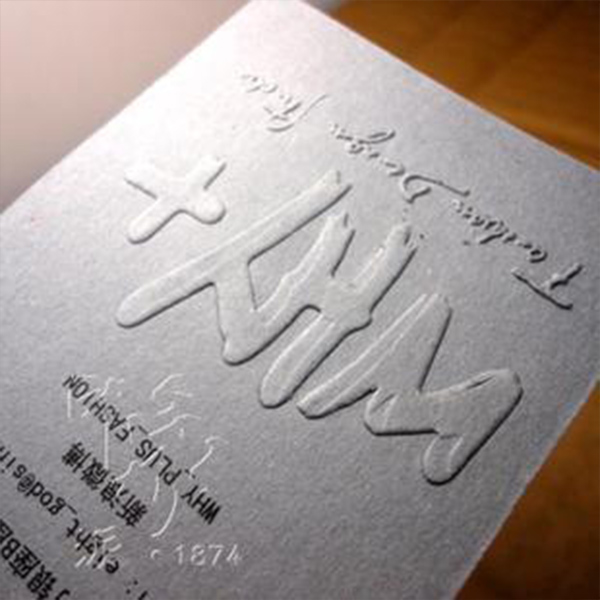

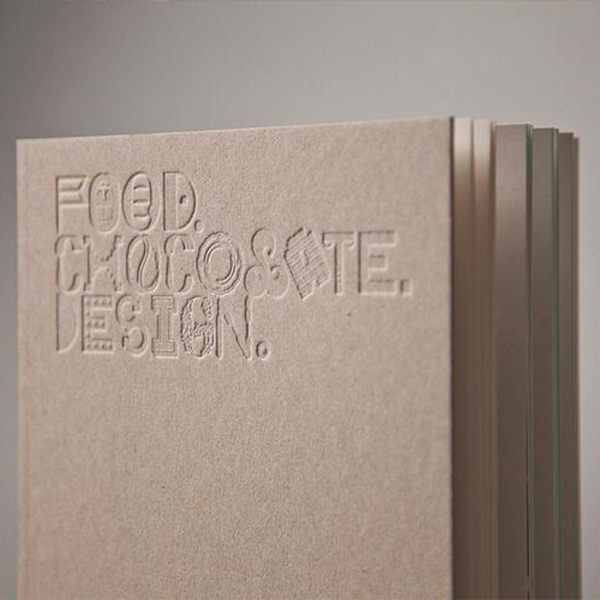

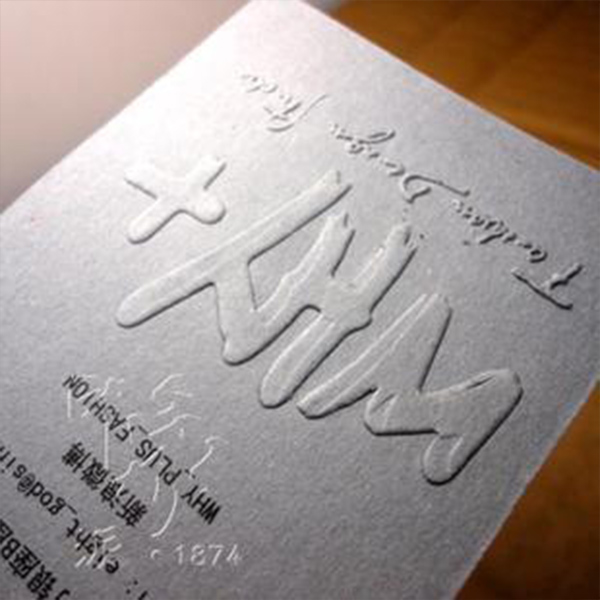

Adding foiling/UV coating for premium tactile effects

Steel-rule cutting with ±0.3mm precision for 3D shapes

Auto-folding & gluing joints (PVA adhesive cure in 3s)

Removal of dust, adhesive residue, and contaminants from packaging surfaces

Identify and segregate packaging with surface wrinkling, color deviation, or structural damage

Each box pack by poly bag , put into 5 layer carton shipping box

Custom packaging is the silent ambassador of your brand.

Precision cutting raw paperboard to press-readywidths (士0.5mm tolerance)

CMYK / Pantone offset printing with color accuracy

Bonding BOPP/PE films for scratch resistance (gloss/matte options)

Adding foiling/UV coating for premium tactile effects

Steel-rule cutting with ±0.3mm precision for 3D shapes

Auto-folding & gluing joints (PVA adhesive cure in 3s)

Removal of dust, adhesive residue, and contaminants from packaging surfaces

Identify and segregate packaging with surface wrinkling, color deviation, or structural damage

Each box pack by poly bag , put into 5 layer carton shipping box

Whatever the occasion, whether you’re buying for yourself or to distribute, we have it all! Send us inquiry to find out about our volume discounts.